Overview

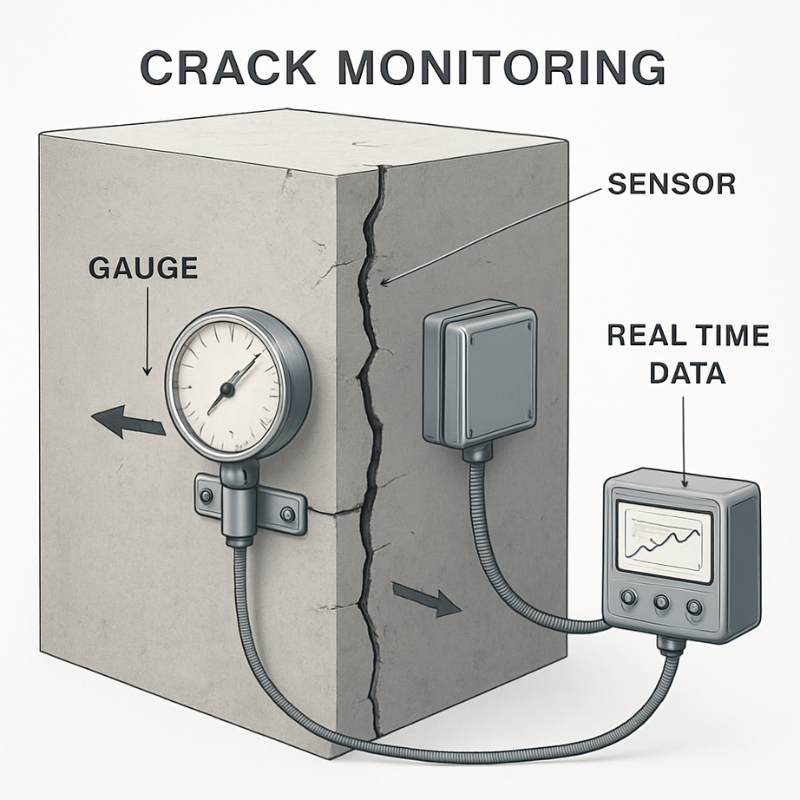

Techniques for crack monitoring include visual inspections, mechanical gauges, strain sensors, digital displacement sensors, and automated data logging systems. Data collected allows precise measurement of crack width, depth, and growth patterns. By analyzing this data, engineers can make informed decisions on structural repairs, reinforcement, and preventive measures, enhancing safety, durability, and long-term asset management.

Properties

- Tracks crack width and movement

- Provides data-driven assessment

- Non-intrusive monitoring methods

- Supports long-term evaluation

Applications

- Buildings and infrastructure

- Bridges and retaining structures

- Tunnels and underground works

- Heritage and sensitive structures

Advantages

- Enables early detection of issues

- Supports accurate repair planning

- Reduces unnecessary interventions

- Enhances structural safety

Workflow

Our Process, Step by Step

Consultation & Assessment

Every project begins with a thoughtful consultation where we take the time to understand your vision, technical needs, and project challenges. Our team reviews available data, studies the site environment, and discusses your priorities in detail. This collaborative approach ensures we start with a clear understanding of the scope and set a strong foundation for success.

Site Investigation & Analysis

Before proposing solutions, we carry out comprehensive geotechnical surveys, soil sampling, and structural evaluations. These tests provide insights into ground behavior, material strength, and potential risk factors. By combining field data with advanced modeling, we ensure that every recommendation is grounded in scientific accuracy and tailored to your specific site conditions.

Customized Solution Design

No two projects are alike, which is why our designs are never one-size-fits-all. We create specialized engineering strategies that align with your objectives, budget, and timelines. Whether it’s ground stabilization, chemical grouting, or structural reinforcement, our solutions are optimized for long-term durability, cost efficiency, and compliance with international standards.

Implementation & Monitoring

Execution is carried out with precision by our skilled engineers and technicians using world-class equipment and materials. During implementation, we continuously monitor key parameters such as pressure, flow, and ground response to ensure accuracy and safety. Our proactive management reduces downtime, minimizes risks, and guarantees that the solution performs as intended on-site.

Handover & Ongoing Support

We don’t just deliver projects—we ensure lasting value. Once execution is complete, we perform rigorous quality checks, provide detailed documentation, and hand over a solution that is ready for long-term performance. Even after completion, our team remains a trusted partner, offering technical support, guidance, and maintenance advice to secure the future of your infrastructure.

Our Products

Product 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Setting & Hardening Properties

Mechanical Properties

Durability Factors

Specialized Performance Parameters

Product 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Setting & Hardening Properties

Mechanical Properties

Durability Factors

Specialized Performance Parameters

Product 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.